R&D

Facing customers’ requirement, Everest is always improving our technique and equipment. In addition to technology investment, Everest also focuses on the improvement of our software. Everest has continued to increase our investment in technology advancement to enhance our position at the forefront of new products and system development for customer requiring innovation. This innovation can help customer and Everest keep pace with today’s competitive, fast-moving and ever-hanging marketplace.

Mold design

Solution design

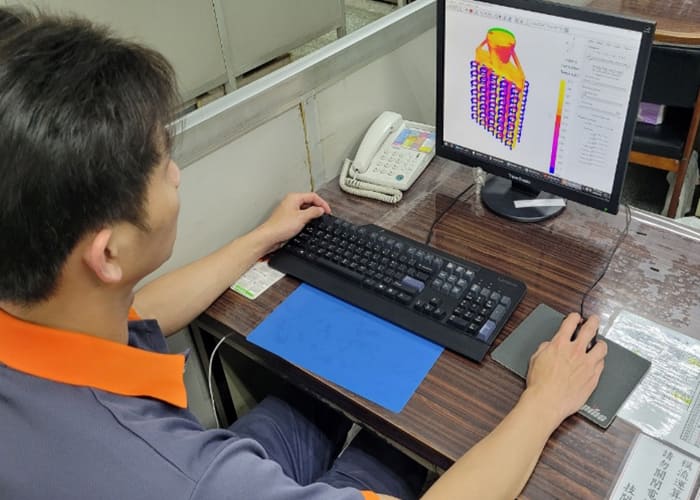

Casting Moldflow Analysis

3D Printer

VDG – Reference Sheet P690

Linear tolerances

| Range (Tolerance ) Zone | D1 | D2 | D3 | |||||

|---|---|---|---|---|---|---|---|---|

| (in mm) | Field | GTA | Fled | GTA | Fled | GTA | ||

| Over 0 | to | 6 | 0.30 | 14 | 0.24 | 13.5 | 0.2 | 13 |

| Over 6 | to | 10 | 0.36 | 0.28 | 0.22 | |||

| Over 10 | to | 18 | 0.44 | 0.34 | 0.28 | |||

| Over 18 | to | 30 | 0.52 | 0.4 | 0.34 | |||

| Over 30 | to | 50 | 0.80 | 14.5 | 0.62 | 14 | 0.5 | 13.5 |

| Over 50 | to | 80 | 0.90 | 0.74 | 0.6 | |||

| Over 80 | to | 120 | 1.10 | 0.88 | 0.7 | |||

| Over 120 | to | 180 | 1.60 | 15 | 1.3 | 14.5 | 1.0 | 14 |

| Over 180 | to | 250 | 2.40 | 15.5 | 1.9 | 15 | 1.5 | 14.5 |

| Over 250 | to | 315 | 2.60 | 2.2 | 1.6 | |||

The GTA general casting tolerance are equivalent to DIN 1680, part 2

*GTA plus supplement

D1 applies for all untoleranced dimensions

D2 applies for all dimensions to be tolerance.

D3 can only met for certain dimensions and must be agreed with castings manufacturer.

*GTA plus supplement

D1 applies for all untoleranced dimensions

D2 applies for all dimensions to be tolerance.

D3 can only met for certain dimensions and must be agreed with castings manufacturer.

Tolerance of wall thickness

| Smallest side of surface | ||||

|---|---|---|---|---|

| (in mm) | ||||

| up | to | 50 | +/- | 0.25 |

| Over 50 | to | 100 | +/- | 0.3 |

| Over 100 | to | 180 | +/- | 0.4 |

| Over 180 | to | 315 | +/- | 0.5 |

Surface roughness

| Surface standards | CLA | Ra | Rz | Ry |

|---|---|---|---|---|

| (μinch) | (μmm) | (μmm) | (μmm) | |

| N 7 | 63 | 1.6 | 6.3 | 6.3 |

| N 8 | 125 | 3.2 | 12.5 | 12.5 |

| N 9 | 250 | 6.3 | 25 | 25 |

N9 is the normal delivery condition

Others

- Biggest dimension: 300*300 mm

- Smallest dimension: 5.0*5.0 mm

- Biggest weight: 30 kg

- Smallest weight: 0.003kg

- Smallest wall thickness: 2.5mm(Partial 1.5 mm)